A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_URI::$config is deprecated

Filename: core/URI.php

Line Number: 101

Backtrace:

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Router::$uri is deprecated

Filename: core/Router.php

Line Number: 127

Backtrace:

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$benchmark is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$hooks is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$config is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$log is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$utf8 is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$uri is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$exceptions is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$router is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$output is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$security is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$input is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$lang is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$load is deprecated

Filename: core/Controller.php

Line Number: 78

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$db is deprecated

Filename: core/Loader.php

Line Number: 396

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_DB_mysqli_driver::$failover is deprecated

Filename: database/DB_driver.php

Line Number: 371

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Return type of CI_Session_database_driver::open($save_path, $name) should either be compatible with SessionHandlerInterface::open(string $path, string $name): bool, or the #[\ReturnTypeWillChange] attribute should be used to temporarily suppress the notice

Filename: drivers/Session_database_driver.php

Line Number: 129

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Return type of CI_Session_database_driver::close() should either be compatible with SessionHandlerInterface::close(): bool, or the #[\ReturnTypeWillChange] attribute should be used to temporarily suppress the notice

Filename: drivers/Session_database_driver.php

Line Number: 280

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Return type of CI_Session_database_driver::read($session_id) should either be compatible with SessionHandlerInterface::read(string $id): string|false, or the #[\ReturnTypeWillChange] attribute should be used to temporarily suppress the notice

Filename: drivers/Session_database_driver.php

Line Number: 151

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Return type of CI_Session_database_driver::write($session_id, $session_data) should either be compatible with SessionHandlerInterface::write(string $id, string $data): bool, or the #[\ReturnTypeWillChange] attribute should be used to temporarily suppress the notice

Filename: drivers/Session_database_driver.php

Line Number: 208

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Return type of CI_Session_database_driver::destroy($session_id) should either be compatible with SessionHandlerInterface::destroy(string $id): bool, or the #[\ReturnTypeWillChange] attribute should be used to temporarily suppress the notice

Filename: drivers/Session_database_driver.php

Line Number: 297

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Return type of CI_Session_database_driver::gc($maxlifetime) should either be compatible with SessionHandlerInterface::gc(int $max_lifetime): int|false, or the #[\ReturnTypeWillChange] attribute should be used to temporarily suppress the notice

Filename: drivers/Session_database_driver.php

Line Number: 335

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: Warning

Message: ini_set(): Session ini settings cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 282

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: Warning

Message: session_set_cookie_params(): Session cookie parameters cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 289

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: Warning

Message: ini_set(): Session ini settings cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 304

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: Warning

Message: ini_set(): Session ini settings cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 314

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: Warning

Message: ini_set(): Session ini settings cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 315

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: Warning

Message: ini_set(): Session ini settings cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 316

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: Warning

Message: ini_set(): Session ini settings cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 317

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: Warning

Message: ini_set(): Session ini settings cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 375

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: Warning

Message: session_set_save_handler(): Session save handler cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 110

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: Warning

Message: session_start(): Session cannot be started after headers have already been sent

Filename: Session/Session.php

Line Number: 143

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$session is deprecated

Filename: core/Loader.php

Line Number: 1283

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$form_validation is deprecated

Filename: core/Loader.php

Line Number: 1283

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: Warning

Message: "continue" targeting switch is equivalent to "break". Did you mean to use "continue 2"?

Filename: libraries/Grocery_CRUD.php

Line Number: 2835

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: Warning

Message: "continue" targeting switch is equivalent to "break". Did you mean to use "continue 2"?

Filename: libraries/Grocery_CRUD.php

Line Number: 2841

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: Warning

Message: "continue" targeting switch is equivalent to "break". Did you mean to use "continue 2"?

Filename: libraries/Grocery_CRUD.php

Line Number: 2878

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: Warning

Message: "continue" targeting switch is equivalent to "break". Did you mean to use "continue 2"?

Filename: libraries/Grocery_CRUD.php

Line Number: 2884

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: Warning

Message: "continue" targeting switch is equivalent to "break". Did you mean to use "continue 2"?

Filename: libraries/Grocery_CRUD.php

Line Number: 2936

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: Warning

Message: "continue" targeting switch is equivalent to "break". Did you mean to use "continue 2"?

Filename: libraries/Grocery_CRUD.php

Line Number: 2942

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$grocery_crud is deprecated

Filename: core/Loader.php

Line Number: 1283

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$image_crud is deprecated

Filename: core/Loader.php

Line Number: 1283

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$Common is deprecated

Filename: core/Loader.php

Line Number: 358

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Home::$data is deprecated

Filename: controllers/Home.php

Line Number: 13

Backtrace:

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property MY_Loader::$benchmark is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home/mathimaaxx/public_html/application/core/MY_Loader.php

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property MY_Loader::$hooks is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home/mathimaaxx/public_html/application/core/MY_Loader.php

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property MY_Loader::$config is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home/mathimaaxx/public_html/application/core/MY_Loader.php

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property MY_Loader::$log is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home/mathimaaxx/public_html/application/core/MY_Loader.php

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property MY_Loader::$utf8 is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home/mathimaaxx/public_html/application/core/MY_Loader.php

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property MY_Loader::$uri is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home/mathimaaxx/public_html/application/core/MY_Loader.php

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property MY_Loader::$exceptions is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home/mathimaaxx/public_html/application/core/MY_Loader.php

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property MY_Loader::$router is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home/mathimaaxx/public_html/application/core/MY_Loader.php

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property MY_Loader::$output is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home/mathimaaxx/public_html/application/core/MY_Loader.php

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property MY_Loader::$security is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home/mathimaaxx/public_html/application/core/MY_Loader.php

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property MY_Loader::$input is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home/mathimaaxx/public_html/application/core/MY_Loader.php

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property MY_Loader::$lang is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home/mathimaaxx/public_html/application/core/MY_Loader.php

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property MY_Loader::$load is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home/mathimaaxx/public_html/application/core/MY_Loader.php

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property MY_Loader::$db is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home/mathimaaxx/public_html/application/core/MY_Loader.php

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property MY_Loader::$session is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home/mathimaaxx/public_html/application/core/MY_Loader.php

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property MY_Loader::$form_validation is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home/mathimaaxx/public_html/application/core/MY_Loader.php

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property MY_Loader::$grocery_crud is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home/mathimaaxx/public_html/application/core/MY_Loader.php

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property MY_Loader::$image_crud is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home/mathimaaxx/public_html/application/core/MY_Loader.php

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property MY_Loader::$Common is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home/mathimaaxx/public_html/application/core/MY_Loader.php

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property MY_Loader::$data is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home/mathimaaxx/public_html/application/core/MY_Loader.php

File: /home/mathimaaxx/public_html/application/controllers/Home.php

File: /home/mathimaaxx/public_html/index.php

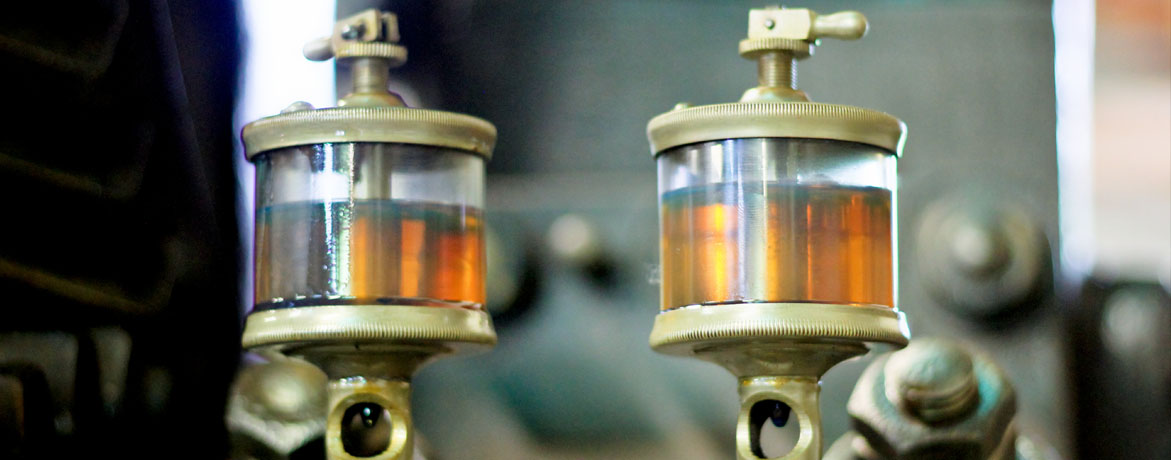

Lubricant

Our Products

MAAXX Soluble Cutting Oil

The most significant players in the manufacturing and supplying Soluble Cutting Oil. Our Soluble Cutting Oil is generally used for emulsification and forms a milky white emulsion. Our MAAXX oil is suitable for water hardness of 400 ppm. The product confirms to IS:1115/86 specification.

Description

Contains high level emulsifiers

Rust protection

Excellent Cooling

Lubricity

Stable emulsion with water at high dilution

Good Surface finishing

MAAXX Super is a soluble type superior grade cutting oil, which form milky emulsion with water. It is manufactured from specially selected base oil having excellent solubility. The emulsion formed is homogenous and stable in nature, MAAXX Cutting contains special rust inhibitors, which imparts, anti-rust and anti-corrosive properties to the emulsion. Carefully selected biocide is added to prevent bacterial growth in emulsion.

Application MAAXX COOLANT

Is recommended for variety of metal working operations on ferrous and non-ferrous metals such as cutting, cold rolling of steel, and hot rolling of aluminums, special rolling of stainless steel etc. the most common emulsion strength used for machining range is from 5-10% depending on the severity of machining. More dilute emulsion is recommended. For stable emulsion, oil should always be added to water and not vice – versa, with continuous stirring.

Metal grinding

Cutting operation

Drilling

Milling

Benefits

Has superior cooling and lubricating properties

Excellent surface finish and minimum tool water

Provides long lasting stable emulsion due to critically selected biocide.

Protect work – piece, machine components, and tool material from rust and corrosion

Excellent medium as a coolant and lubricant while metal cutting, used as an emulsion with water.

Exception anti corrosive & antirust properties.

Stable milky emulsion with water having hardness range 400 ppm

Do not decompose, retains physical properties.

Specification

Sr.No

Test Parameter

Specification

1.

Emulsion Test : 20:1 ratio in water of 400ppm harness (as CaCO3)

Passes the test

2.

Frothing Test : 5:1, 20:1 rat in water of 200ppm hardness (as CaCO3)

No Frothing

3.

Creaming Test : 5:1, 20:1 ratn water of 200ppm hardness (as CaCO3)

No Creaming

4.

Copper, Strip corrosion Test : At 100? C for 3 hours

Not worse than No.1

5.

Flash Point : COC,

180?C

6.

Viscosity : @ 40?C CST

26 to 28

7.

Cast iron Corrosion Test

Test plate shall be free from corrosion and surface discoloration.